Compensator module for 2 or more boilers in cascade SLAVE

-

DESCRIPTION

General features0

Slave module for multifunctional, expandable, control units with remote control EV87 and EV90

It is suitable for all heating systems types where it is necessary to spread the capacity over several boilers connected in cascade.

The module allows to completely manage 2 boilers in cascade, commanding automatically both butterfly valves and burners.

- Boiler temperature minimum or maximum limits.

- Boilers rotation adjustable from 1 to 99 days.

- Maximum number of controlled boilers – 8 (2 boilers x 4 modules).

- Parameters visualization and modification by means of FANBUS from EV90 or EV87 MAS TER.

- Local programming or via SMS messages (with GSM modem) or via remote computer (with analog PSTN modem) via the communication bus (FANBUS) and the MAS TER EV90 or EV87.

- Addressing through jumpers on the external terminal board.

- TX and RX signaling Led for connection with FANBUS, butterfly valves and burners control.

Electric features- Power supply: 230V 50Hz.

- Consumption: 5 VA.

- 4 output relays: 2 for butterfly valve control, 2 for burner control.

- 1 communication channel – FANBUS.

- 1 analog input for delivery temperature (NTC type probes – EC15 or EC16).

- Voltage free contacts.

-

ADVANTAGES

0

Slave module for multifunctional, expandable, control units with remote control EV87 and EV90

It is suitable for all heating systems types where it is necessary to spread the capacity over several boilers connected in cascade.

The module allows to completely manage 2 boilers in cascade, commanding automatically both butterfly valves and burners.

Advantages -

TECHNICAL SPECIFICATION

CODE POWER SUPPLY CONTACTS RATING OPERATION ADMISSIBLE TEMPERATURE PROTECTION DEGREE EV91C 230Vac 50Hz 5A - 250Vac 0 ÷ 50 °C IP40 back-panel -

HOMOLOGATION AND INSTALLATION

Homologation

- Complies with the law 373, law n.10 dated 9 of January 1991 and D.P.R.412 dated 26 of August 1993.

- Complies with EN 60730-2-9; EN 60730-2-7 standards.

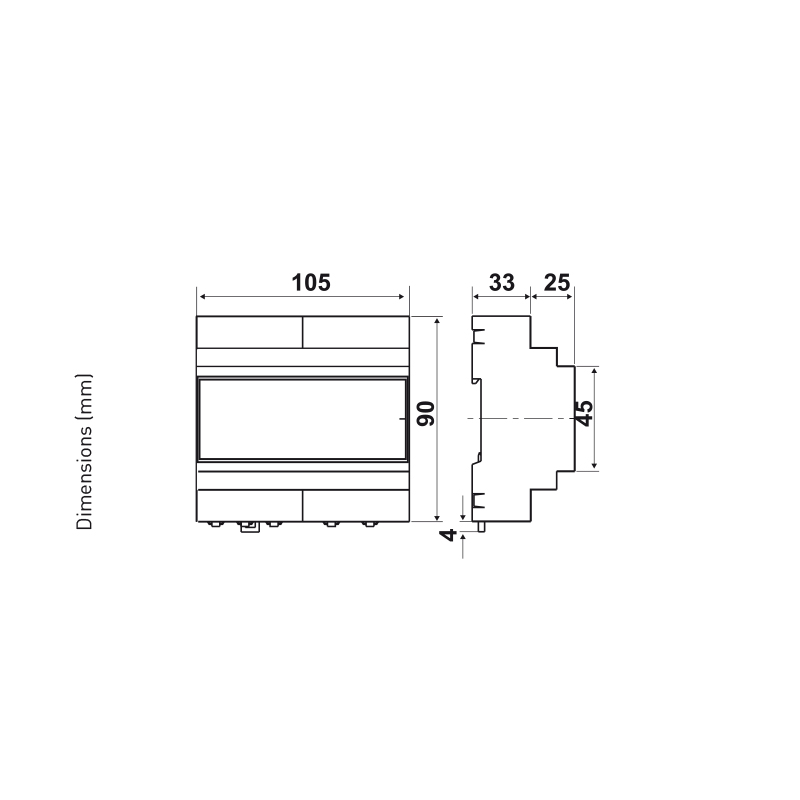

Installation and use- DIN-rail mounting (6 modules).

- To ensure an adequate protection install the device on the DIN-rail within a framework.

- The removable terminals facilitate the wiring and a possible replacement.

- Through a measuring probe, EV91C detects the temperature value of the delivery collector. If the temperature value falls below a preset value for a certain period of time, the device opens the butterfly valve and turns on the relevant burner to switch on the first auxiliary boiler.

- If after a certain period of time one boiler is not enough to bring the temperature below the required threshold, EV91C inserts the second boiler and so on.

- In case, the collector temperature should remain at the set values , the controller will disconnect the boilers, first switching off the burner and, after an adjustable delay, closing the butterfly valves.

- For controlling more than 2 boilers, it is necessary to add more EV91C modules in order to meet the requirements.

- Maximum 4 modules may be connected for a total of 8 boilers in cascade.

- TECHNICAL LITERATURE

-

FAQS