Bladed level controls for powders and granules

-

DESCRIPTION

General features0

Suitable to control the level of powders and granules in storages or tanks, for high and low level signalling, for transporter control, for feeders, etc.

- Aluminium alloy body.

- Stainless steel 4-blade propeller.

- Clutch shaft mounted on sealed ball bearings.

- Output connections with shockproof thermoplastic cable gland G 1/2” .

- Storage and transport temperature: -25 ÷70°C.

- Unit weight: 2.2 Kg.

Electric features- Synchronous motor: 4.5VA, supply voltage 230Va.c. 50Hz.

- 2 SPDT microswitches : one for motor control, one for operation.

- Rated insulation voltage Ui 380V~

- Continuous duty rated current Ith 10A

-

ADVANTAGES

0

Suitable to control the level of powders and granules in storages or tanks, for high and low level signalling, for transporter control, for feeders, etc.

Advantages -

TECHNICAL SPECIFICATION

CODE LEVEL DIFFERENTIAL POWER SUPPLY OPERATING TEMPERATURE PROTECTION DEGREE ASE fixed 50 mm 230 Vac -20 ÷ 80 °C IP54 -

HOMOLOGATION AND INSTALLATION

Homologation

- Complies with CEI- EN 60947-5-1 standards.

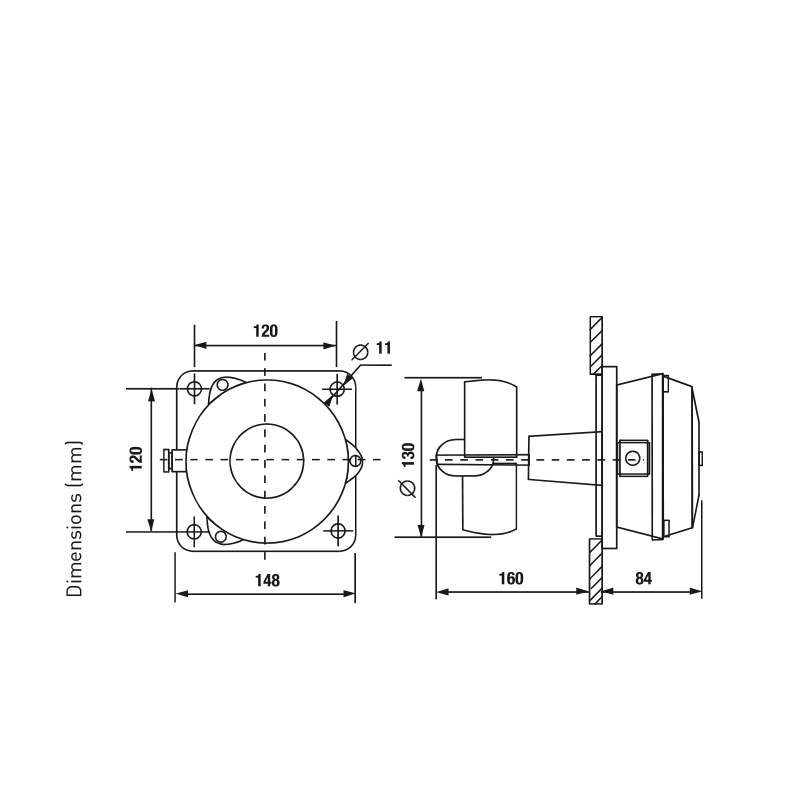

Installation and use- Flange connection suitable for horizontal and vertical installation.

- It is recommended to install ASE away from storages loading places and away from the presence of materials with high specific gravity, protecting by a reflective device the shaft and the propeller.

MAXIMUM LEVEL

- Device installation usually is carried out on the head side of the tank.

MINIMUM AND MEDIUM LEVEL

- Usually, the device is mounted horizontally.

- For small tanks, extending axle you can mount as well on the head side.

- For lightweight materials and fluids are used screws with large blades. For large sizes materials are required screws with flexible blades.

- Elements, that determine the operation are the synchronous motor and its torque.

- The material impedes propeller rotation to a stop.

- Suitable to control materials (such as granules and powders) with a specific gravity of approximately 0,7 kg/dm³.

- When the material hampers the screw rotation, the electric motor with the force of its torque acts on the microswitch, which closes or opens the electrical circuit (24 ÷ 280Vac 10A) while the second microswitch shuts down the motor disconnecting the power supply.

- Reducing the level, the propeller is released and through the return spring the motor and microswitches automatically pass into the initial position.

- N.B. If you want to use for control a second microswitch, used voltage should be the same with motor’s supply voltage.

- TECHNICAL LITERATURE

-

FAQS