Mechanical level controls for under pressure systems up to 16 bar

-

DESCRIPTION

General features0

Suitable to control liquid level in tanks under pressure, autoclaves, steam generators with control contact for supply pump and with minimum level control.

- This level control is made of a stainless steel ball float and a flange for pressure up to 25 bar.

- Ball-shaped body made of shockproof and high density cast iron.

- Ball-shaped mercury switches for high temperatures.

- Differential level adjustment device.

- Execution: armored.

- Viewing window protected by a double glass for ball-shaped mercury switches visibility.

- Conductors outputs with metallic flexible tubes.

- A41A unit weight 5.4 Kg

- A41B unit weight 5.1 Kg

Electric features- Two mercury bulb switches for high temperatures: one switch for pump control, another, double, to control the burner and the minimum level alarm signal.

-

ADVANTAGES

0

Suitable to control liquid level in tanks under pressure, autoclaves, steam generators with control contact for supply pump and with minimum level control.

Advantages -

TECHNICAL SPECIFICATION

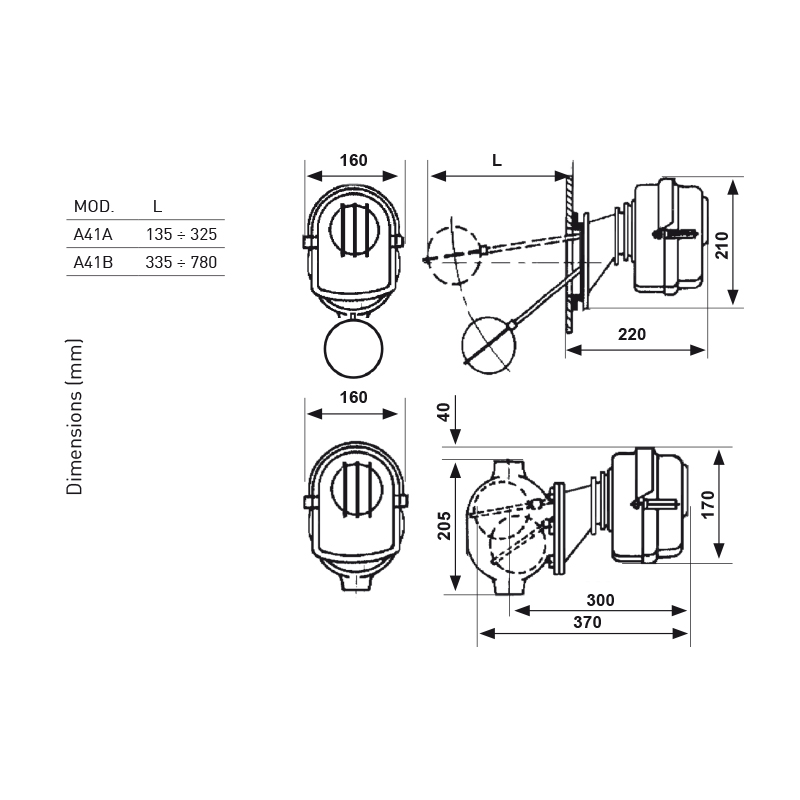

CODE CONNECTION LEVEL DIFFERENTIAL MAXIM. OPERATING PRESSURE MAXIM. LIQUID TEMPERATURE CONTACT RATING PROTECTION DEGREE A41A Flange connection with visible float 25 ÷ 50 mm 16 bar 200 °C 5(2)A 250Vca IP54 25 ÷ 75 mm 16 bar 200 °C 5(2)A 250Vca IP54 A41B Flange connection with visible float 55 ÷ 210 mm 16 bar 200 °C 5(2)A 250Vca IP54 65 ÷ 305 mm 16 bar 200 °C 5(2)A 250Vca IP54 95 ÷ 370 mm 16 bar 200 °C 5(2)A 250Vca IP54 140 ÷ 570 mm 16 bar 200 °C 5(2)A 250Vca IP54 -

HOMOLOGATION AND INSTALLATION

Homologation

- Conformity with CEI-EN 60947-5-1 standards.

Installation and use- Flange connection for direct mounting on the tank; submersible float in the tank.

- TECHNICAL LITERATURE

-

FAQS