Electronic level controls with internal safety barrier

-

DESCRIPTION

General features0

Liquids level control in hazardous areas or with high temperatures

Suitable to control and monitor the fluid level in open and under pressure tanks up to 10 bars. Used in installations with autoclaves to control the filling pump or automatically restore the air vessel.

- The device transmits a galvanically protected switching signal.

- System security is ensured through sensors of relevant standards EN 60947-5-6 (NAMUR) or by the mechanical switches which are located in the danger zone.

- LED indicators on the front side.

- Status display at the input, as well at the output.

- Six switches are located on the front panel of the device, used to configure the outputs for each channel separately and for monitoring the input control circuit for cable breakage or short-circuit.

- Storage and transport temperature: -25 ÷ 60 °C.

Electric features- Completely independent power supply of each channel with its own 24V or 250V 50Hz power supplier.

-

ADVANTAGES

0

Liquids level control in hazardous areas or with high temperatures

Suitable to control and monitor the fluid level in open and under pressure tanks up to 10 bars. Used in installations with autoclaves to control the filling pump or automatically restore the air vessel.

Advantages -

TECHNICAL SPECIFICATION

CODE POWER SUPPLY INPUT(S) IN DANGER ZONE OUTPUT(S) IN SAFE ZONE PROTECTION DEGREE EA31MA 220Vac-50Hz NA/NC unprotected contacts voltage free 2 relays with 1 SPDT 250V-2,5A - 100VA IP40 -

HOMOLOGATION AND INSTALLATION

Homologation

- Protection [EEx-ia] IIC, [EEx-ia] IIB, EN 60947-5-6 (NAMUR) standards.

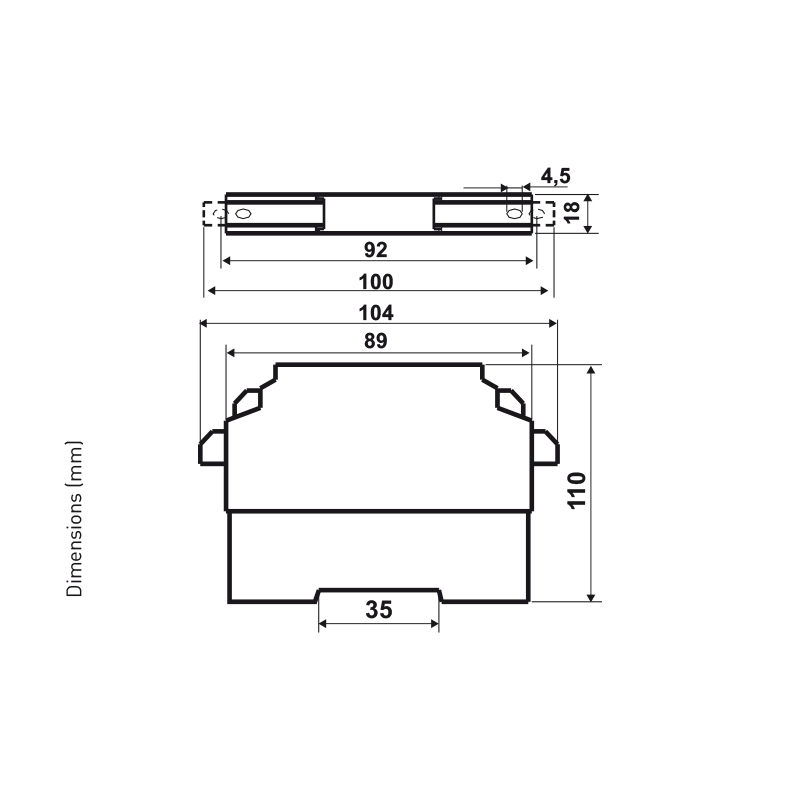

Installation and use- DIN-rail mounting.

- The device is suitable for DIN-rail (EN50022) mounting or on the panel.

- The devices of the same type can be installed on each other.

- Cable connection to the side terminals.

- Removable terminals are equipped with security devices (red key), which prevents accidental wrong connection.

- Control signals come from voltage free contacts positioned in the hazardous area and are transmitted to the outputs of the control unit by 2 relays with voltage free switching contacts.

- In order to ensure safety working in hazardous areas where are meet fire or explosion risks (diesel vessel, wastewater pits in which are accumulated inflammable or explosive vapours) it is necessary to connect to the electrical circuit EEx-ia protective barrier.

- The system, whose components are sold separately or bundled, comprises:

– A96 float level control;

– Control unit with internal safety barrier EA31MA. - The control unit is designed for 1 or 2 level controls connection. This allows you to control one level or to control the pump from minimum to maximum level. In case of liquids which do not pose explosion or fire risks, EA31MA switch are not necessary.

- A96 level control can be connected directly to the contactor coil.

- TECHNICAL LITERATURE

-

FAQS